ALTERNATOR REMOVAL AND INSTALLATION - Hallo semua

Bengkel Karya Prima Motor, Pada Postingan kali ini yang berjudul ALTERNATOR REMOVAL AND INSTALLATION, telah kami persiapkan dengan baik untuk anda baca dan ambil informasi didalamnya. mudah-mudahan isi postingan

Artikel Artikel, ini dapat anda pahami. dan bermanfaat, selamat membaca.

Judul :

ALTERNATOR REMOVAL AND INSTALLATIONlink :

ALTERNATOR REMOVAL AND INSTALLATION

Baca juga

ALTERNATOR REMOVAL AND INSTALLATION

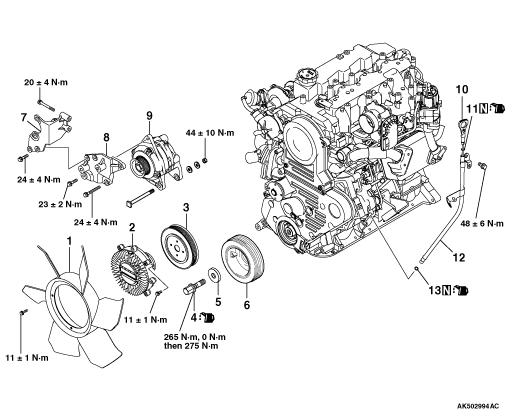

REMOVAL AND INSTALLATION

|

|

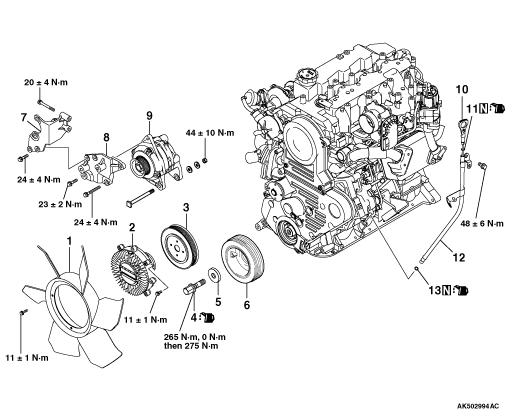

| Removal steps

|

|

| 1.

| Cooling fan

|

|

| 2.

| Fan clutch

|

|

| 3.

| Water pump pulley

| <<A>>

| >>A<<

| 4.

| Crankshaft pulley bolt

|

| >>A<<

| 5.

| Crankshaft pulley washer

| <<B>>

| >>A<<

| 6.

| Crankshaft pulley

|

|

| 7.

| Power steering pump bracket "A"

|

|

| 8.

| Power steering pump bracket "B"

|

|

| 9.

| Alternator assembly

|

|

| 10.

| Oil level gauge

|

|

| 11.

| O-ring

|

|

| 12.

| Oil level gauge guide

|

|

| 13.

| O-ring |

| |

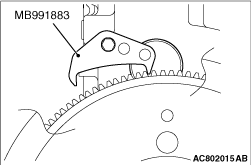

| <<A>> CRANKSHAFT PULLEY BOLT REMOVAL

|

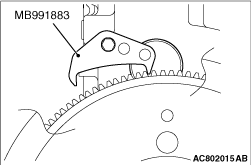

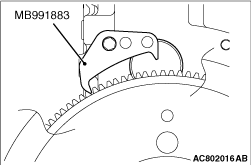

| 1.Use special tool flywheel stopper (MB991883) to secure the flywheel <M/T> or inertia ring <A/T>.

2.Remove the crankshaft pulley bolt.

|

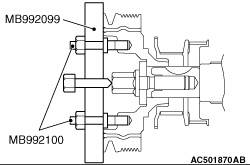

| <<B>> CRANKSHAFT PULLEY REMOVAL

|

| If the crankshaft pulley cannot be removed from the crankshaft, follow the procedure below.

|

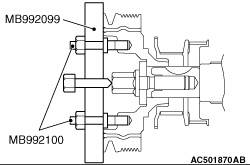

| 1.Install the crankshaft pulley bolt and crankshaft pulley washer to the crankshaft pulley. At this time, the crankshaft pulley bolt must be loosened by 3 to 4 turns from the completely tightened state.

|

| 2.Use the special tools, remove the crankshaft pulley.

- Crank pulley puller (MB992099)

- Crank pulley holder (MB992100)

|

|

INSTALLATION SERVICE POINT |

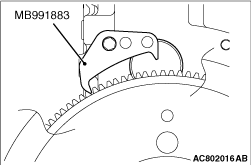

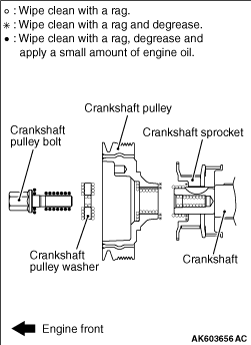

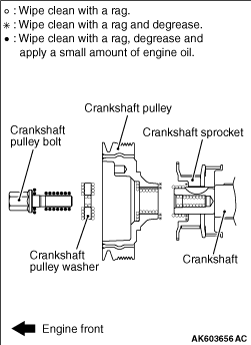

| >>A<< CRANKSHAFT PULLEY /CRANKSHAFT PULLEY WASHER / CRANKSHAFT PULLEY BOLT INSTALLATION

|

| 1.Use special tool flywheel stopper (MB991883) to secure the flywheel <M/T> or inertia ring <A/T> in the same manner as removal.

|

| 2.Wipe the dirt on the crankshaft pulley washer using a rag.

3.Using a rag, wipe the dirt on the crankshaft pulley, the crankshaft sprocket, the thread hole of the crankshaft and then remove the grease.

| note | Degreasing is necessary to prevent decrease in the friction between contacting surfaces.

|

4.Install the crankshaft pulley.

5.Apply an appropriate and minimum amount of engine oil to the threads of crankshaft pulley bolt and lower part of the flange.

6.Install the crankshaft pulley washer to the crankshaft pulley bolt.

7.Tighten the crankshaft pulley bolt to the specified torque of 265 N·m.

8.Loosen the crankshaft pulley bolt completely.

9.Tighten the crankshaft pulley bolt again to the specified torque of 275 N·m.

|

Komentar

Posting Komentar